GPR is a powerful form of condition assessment to identify cracks, rust, or other types of deterioration in concrete structures. Since GPR uses high-frequency radio waves, it doesn’t damage structures and isn’t harmful to people. Still, it provides high-precision imaging to analyze the condition of concrete and to pinpoint corrosion.

How GPR Is Used to Perform Condition Assessments

GPR uses short pulses of electromagnetic energy to detect materials embedded in concrete structures. As the pulse comes up against any embedded interface, a portion of the wave will reflect. In concrete structures, rebar is this common interface. The data collected from the GPR scans is then used to create a clear image of the condition of the concrete. These images can reveal gaps, moisture accumulation, cracks, and corrosion hidden in the concrete.

Why Is Condition Assessment Necessary?

Condition assessment of concrete structures is essential because embedded materials like rebar can corrode. Corrosion happens when the concrete is exposed to moisture (particularly seawater), de-icing chemicals used on roadways, and chemicals found in soil. Contamination from construction materials can also corrode and weaken steel within concrete.

Corrosion of Metals Leads to Concrete Deterioration

The corrosion of metals embedded in concrete structures is a leading cause of their deterioration. When rebar begins to rust, it becomes weaker and starts to lose its ability to support the concrete structure. Rust also causes rebar to expand in volume, which puts added pressure on the concrete surrounding it. This pressure can lead to cracks and chunks of concrete falling from the structure.

If corrosion goes unchecked, structural fatigue and structural collapse can occur. It is believed that the Surfside, FL, condo collapse was due to deterioration that compromised the entire structure, killing nearly 100 innocent victims.

GPR Imaging Can Prevent Code Violations and Costly Repairs

GPR scanning can paint a 3-D image of the location of all rebar in a concrete structure. By using this information, minor problems can be fixed before they turn into building code violations or costly repairs. If you see any of the following issues, there is likely deterioration in the concrete structure that needs to be addressed.

Rusting Rebar

When rebar rusts, it begins to deteriorate and lose its strength. It also will expand, which can put significant pressure on the concrete covering it.

Spalling

Spalling refers to chunks of concrete popping or falling off the structure. There are a few reasons this happens. The first reason is mechanical damage, such as if a hard metal object hits the concrete with significant force. Another way this happens is when rusting rebar pushes on the concrete, causing cracks to form and concrete to break off.

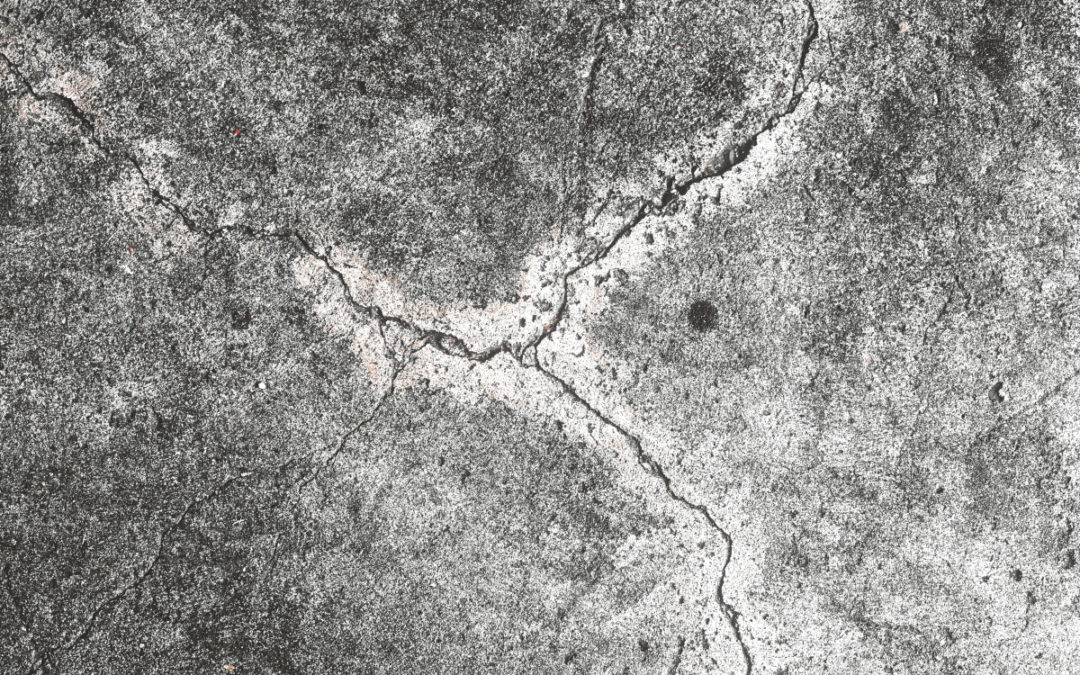

Shrinkage

When concrete is initially mixed and poured, it will have excess water in it. As the concrete hardens, it loses the excess water and shrinkage cracks can form. If too much water was added during pouring, the cracking can be an issue. These cracks will make the concrete weaker and allow moisture to reach the rebar.

Exposed Rebar

Inadequate concrete coverage can leave rebar exposed. Exposed rebar is a building code violation and a safety hazard. Additionally, rebar that isn’t properly covered will be exposed to more moisture and is more likely to rust.

Rock Pockets

Rock pockets are caused by improperly vibrated or placed concrete. This is a frequent problem when concrete didn’t have enough water added when it was being mixed. Rock pockets can lead to rusty rebar and a weaker concrete structure.

Visible Rust Near Cracks

Any visible rust near a crack in a concrete structure needs to be repaired. This is usually a sign that the rebar is rusting and means that moisture is getting into the concrete. This issue should be addressed immediately to stop the concrete from deteriorating.

Benefits of GPR for a Concrete Condition Assessment

Time and again, GPR has proven to be a safer, more affordable, and higher-quality imaging technology than X-ray. It is the technology of choice to assess the beginning, middle, and final stages of any project involving concrete for the following reasons.

Safety

GPR is the safest form of concrete assessment. Rather than using radioactive sources like X-ray does, GPR uses electromagnetic energy. Because of this, GPR emits far less radiation and allows sites to stay open for use.

Affordability

GPR is much more affordable than X-ray scanning because sites don’t need to be shut down while scanning is taking place. Additionally, having a concrete condition assessment at the outset of a project can result in significant savings down the line. The sooner issues can be addressed, the safer and more affordable a project is.

Efficiency

Results from GPR assessment of concrete structures are available immediately compared to the hours or days X-ray scanning may require.

Quality

The images that result from GPR are higher resolution and result in a more definitive final image. Additionally, GPR Data Inc. delivers cutting-edge 3D imaging and data documentation to support analysis and characterize problems. These images aid in understanding precisely where issues are and can always be referenced when needed.

Environmentally Friendly

GPR does not disturb the environment, including lawns or landscapes. Low radiation emissions from GPR and low energy usage make it safe to use for sensitive environments and structures.

Request a Quote for GPR Concrete Structure Imaging

GPR Data, Inc.’s state-of-the-art equipment, years of experience, and expert leadership have earned our company clients across many industries. Our capabilities enable us to provide our clients with precise, high-resolution condition assessments and deterioration models that keep workers safe and sites open. In addition to providing concrete condition assessments, GPR Data, Inc. provides the following services:

- Aerial Drone Photos, Mapping & CAD Overlays

- Archaeology & Grave Site Mapping

- Bedrock & Boulder Mapping

- Bridge Deck Inspections

- Environmental Mapping and Exploration

- Pavement Structure Analysis

- Pipeline Inspections and Leak Locating

- Subsurface Utility Locating and Mapping

- Video Pipe Inspection

- Void Detection

To request a quote for concrete structure assessment, contact us online or call 541-345-1075. GPR Data Inc. is headquartered in Eugene, OR. We also have offices in Medford and Portland, as well as Las Vegas, Seattle, and Los Angeles.